Kuyaziwa ukuba umgangatho we-carbide saw blades uhambelana ngokusondeleyo nomgangatho weemveliso ezicutshungulwayo.Ukhetho oluchanekileyo nolufanelekileyo lwee-carbide saw blades lubaluleke kakhulu ekuphuculeni umgangatho wemveliso, ukunciphisa ixesha lokucubungula, kunye nokunciphisa iindleko zokucubungula.

Mhlawumbi ukhathazekile malunga nendlela yokukhetha! Emva koko nceda ufunde eli nqaku ngomonde, ndiyathemba ukuba kufuneka likwazi ukukunceda ngakumbi.

I-Carbide saw blades ibandakanya iiparitha ezahlukeneyo ezifana nohlobo lwentloko ye-alloy cutter, izinto ze-substrate, ububanzi, inani lamazinyo, ubukhulu, iphrofayili yezinyo, i-angle, kunye ne-aperture. Ezi parameters zigqiba amandla okucubungula kunye nokusebenza kokusika kwe-saw blade. Ngoko ke, xa ukhetha i-saw blade, kuyimfuneko ukuba ukhethe i-saw blade ngokuchanekileyo ngokohlobo lwe-sawing material, ubukhulu, isantya sokubona, i-direction of sawing, isantya sokutya kunye nobubanzi bendlela yesarha.

Okokuqala, ukhetho lweentlobo ze-carbide zesamente.

Iintlobo ezisetyenziswa ngokuqhelekileyo ze-carbide ene-cemented yi-tungsten-cobalt kunye ne-tungsten-titanium. Ngenxa yokuba i-tungsten-cobalt-based cemented carbide inempembelelo engcono yokuchasana, isetyenziswa ngokubanzi kwishishini lokulungisa iinkuni. Njengoko umxholo we-cobalt usanda, ukuqina kwempembelelo kunye namandla e-flexural e-alloy kuya kwanda, kodwa ukuqina kunye nokuxhatshazwa kokugqoka kuya kuncipha. Khetha ngokweyona meko.

Okwesibini, ukhetho lwe-substrate.

1. I-65Mn spring steel ine-elasticity enhle kunye ne-plastiki, izinto zezoqoqosho, ukuqina konyango lokushisa okulungileyo, ukushisa okuphantsi kobushushu, ukuguqulwa okulula, kwaye ingasetyenziselwa ii-saw blades ezifuna iimfuno eziphantsi zokusika.

2. Isixhobo seCarbon sensimbi sinomxholo ophezulu wekhabhoni kunye nokuhanjiswa kwe-thermal ephezulu, kodwa ubunzima bayo kunye nokunxiba ukuxhathisa kwehla ngokukhawuleza xa kubonakaliswe kubushushu obungama-200 ℃-250 ℃, i-deformation yonyango lobushushu inkulu, ukuqina akubi, kwaye ixesha elide lilula. ukuqhekeka. Ukuvelisa izixhobo zoqoqosho.

3. Xa kuthelekiswa ne-carbon tool steel, i-alloy tool steel inokumelana nokushisa okungcono, ukumelana nokugqoka kunye nokusebenza kakuhle kokuphatha. Iqondo lobushushu deformation yi 300℃-400℃, nto leyo ifanele ukwenziwa ialloy iibhleyidi ezijikelezayo ezikumgangatho ophezulu.

4. Isixhobo sensimbi esinesantya esiphezulu sinokuqina okulungileyo, ukuqina okuqinileyo kunye nokuqina, kunye nokuguqulwa okuncinci kokushisa. I-ultra-high-strength steel kunye ne-thermoplasticity ezinzileyo kwaye ifanelekile ukuvelisa ii-saw blades eziphezulu ze-ultra-thin.

Okwesithathu, ukhetho lobubanzi.

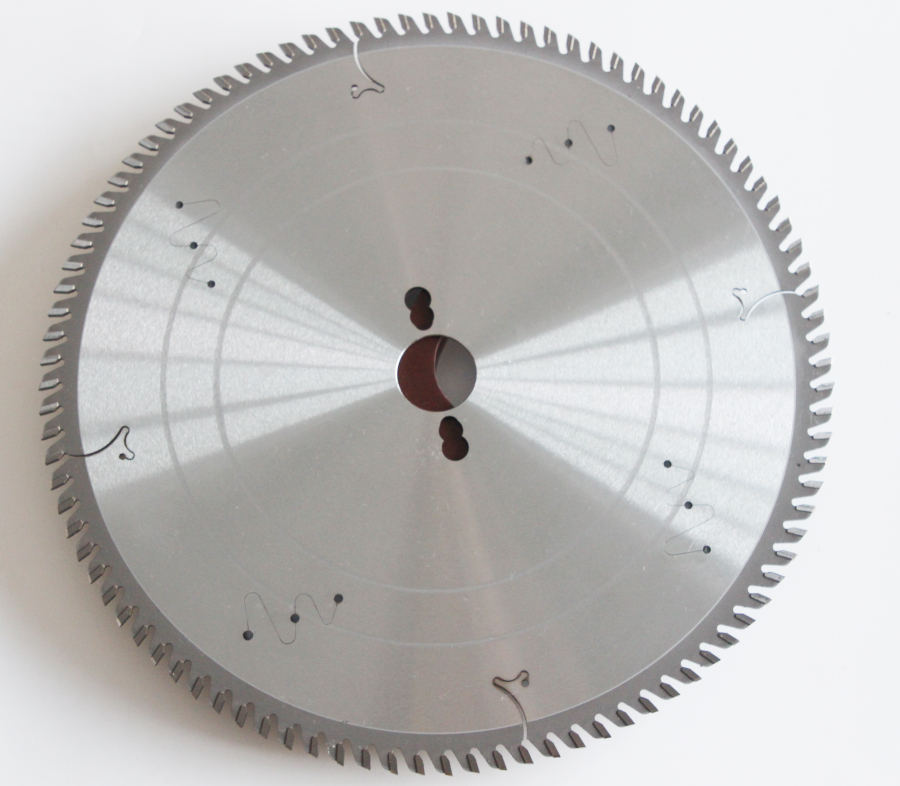

Ububanzi be-saw blade bunxulumene nezixhobo zokusarha ezisetyenzisiweyo kunye nobukhulu bomsebenzi wokusarha. Ububanzi be-saw blade buncinci, kwaye isantya sokusika sincinci; iblade yesarha enkulu ineemfuno eziphezulu kwi-saw blade kunye nezixhobo zokusarha, kunye nokusebenza kakuhle kwesarha nako kuphezulu. I-diameter yangaphandle ye-saw blade ikhethwe ngokweemodeli ezahlukeneyo zeesetyhula.

Okwesine, ukhetho lwenani lamazinyo.

Ngokuqhelekileyo, okukhona inani lamazinyo lithe chatha, iindawo zokusika zinokusikwa ngexesha leyunithi, kokukhona umsebenzi wokusika ungcono, kodwa amazinyo okusika kufuneka asebenzise i-carbide enesamente ngaphezulu, ixabiso lesarha liphezulu, kodwa amazinyo anzima kakhulu , Umthamo we-chip phakathi kwamazinyo uba yincinci, kulula ukubangela ukuba i-saw blade ishushu; ukongeza, maninzi kakhulu amazinyo esarha. Xa inani lokutya lingahambelani, inani lokusika izinyo ngalinye lincinci, eliya kwandisa ukungqubuzana phakathi komgca wokusika kunye ne-workpiece, kwaye ichaphazele ubomi benkonzo yomgca wokusika. Ngokuqhelekileyo izithuba zamazinyo ziyi-15-25mm, kwaye inani elifanelekileyo lamazinyo kufuneka likhethwe ngokuhambelana nezinto eziza kugqitywa.

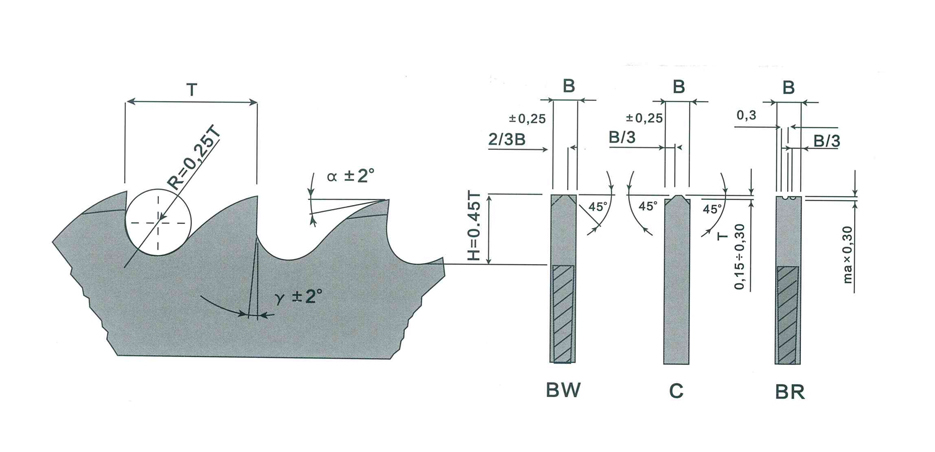

Okwesihlanu, ukhetho lweprofayili yezinyo.

1.Amazinyo asekhohlo nasekunene ngawona asetyenziswa kakhulu, isantya sokusika sikhawuleza, kwaye ukugaya kulula. Ilungele ukusika kunye nokuwela iiprofayili zomthi ezithambileyo neziqinileyo kunye neebhodi zoxinaniso, iibhodi ezinomaleko amaninzi, iibhodi zamasuntswana, njl. njl. ukusika kuzo zonke iintlobo zeeplanga ngeendawo zemithi; iibhleyidi zezinyo lasekhohlo nasekunene ezinerakhi engalunganga zidla ngokusetyenziselwa ukuncamathisela ngenxa yamazinyo azo abukhali kunye nomgangatho olungileyo wokusika, afanele iiphaneli.

2. I-flat tooth saw blade ibuhlungu, isantya sokusika sicotha, kwaye ukugaya yeyona nto ilula. Ikakhulu isetyenziselwa ukukhangela iinkuni eziqhelekileyo, ngexabiso eliphantsi. Isetyenziswa kakhulu kwiincakuba zesaha zealuminiyam ezinobubanzi obuncinci ukunciphisa ukuncamathelisa ngexesha lokusikwa, okanye iiblade zesaha ezikroliweyo ukugcina umzantsi wegroove umcaba.

3. Amazinyo athe tyaba eleli yindibaniselwano yamazinyo etrapezoidal kunye namazinyo asicaba. Ukugaya kunzima ngakumbi. Inokunciphisa ukuqhekeka kwe-veneer ngexesha lokusarha. Ilungele ukubonwa kweepaneli ezahlukeneyo zomthi omnye kunye ne-double veneer kunye neebhodi ezingatshiyo. Ukuthintela ukunamathela, iincakuba zesarha aluminiyam zidla ngokusebenzisa iisarha ezinomthamo omkhulu wamazinyo eleli amazinyo asicaba.

4. Amazinyo eleli ejijelweyo adla ngokusetyenziswa kwincakuba yesarha esezantsi yesarha yendawo yolawulo. Xa sawing panel kabini-ubuso iinkuni-based, isarha uhlengahlengisa ubukhulu ukugqiba grooving kumphezulu ezantsi, kwaye ke isarha main ugqibezela inkqubo sawing yebhodi. Thintela ukuqhekeka komphetho kwincam yesarha.

Ixesha lokuposa: Oct-11-2021